Framing

The foundation of a deck is its frame: the ledger, beam, joists, stringers, are just some of the things that support the decking and railing, and provide a stable structure for a builder to mount and fasten each part on.

Framing Member

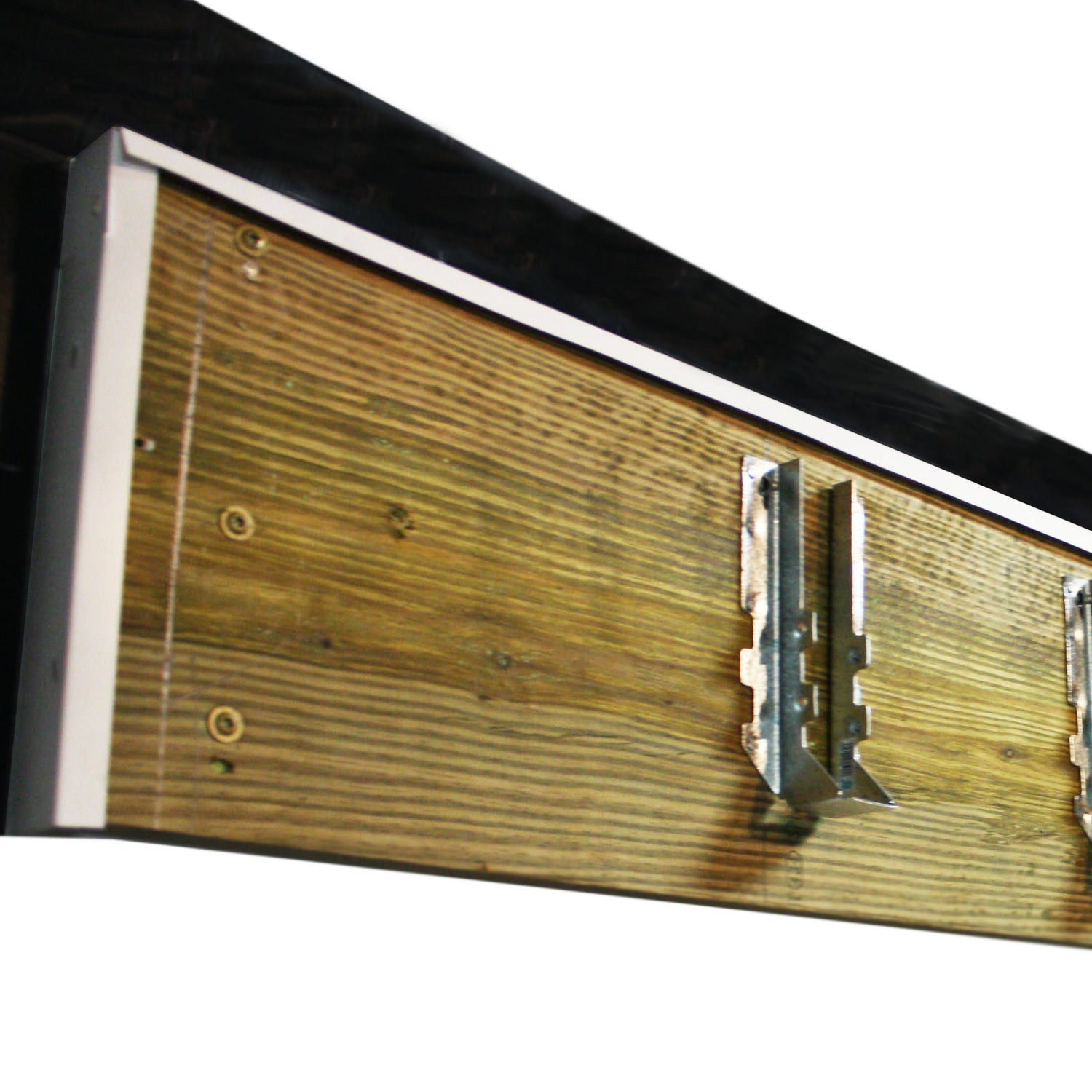

Ledger or Header

Almost every deck starts with a ledger attached to the home that is secured and waterproofed properly. The most common failure point on a deck is the ledger, and it is usually due to rot or inadequate fasteners.

A ledger provides a solid board to secure the joist hangers to the house, and essentially supports one half of the deck.

We recommend ledgers to be a 2x10, or a 2x12 if you wish to secure it to the wall plate for more stability.

Waterproofing

Ledger Flashing and Tape

To keep moisture from rotting the house wall and the ledger, flashing and tape should be used where the ledger meets the house. A piece of flashing with a drip edge allows water running down the house wall to flow over the flashing and away from the house.

Flashing tape is used to keep the flashing in place, and seal the joint where the flashing meets the house wall. Typically a 4" or 6" wide piece of tape is used.

Fasteners

Ledger Screws

Ledgers should be secured to the house with 5" lag screws (or longer) through the house wall, and into the house framing. Simpson SDWS screws or LedgerLok screws are two common options for securing the ledger.

These screws should go through the ledger and land in either the wall plate or a truss. If you can't hit either of these, you may need to add a back board or blocking on the inside of the house.

Setting a Deck Ledger

Connectors

Joist Hangers

Joist hangers come in many sizes and configurations, but what we commonly use for deck joists are single and double 2x10 hangers. These are usually secured to the ledger or flush beam with 1-1/2" nails, and 3" nails are used as shear nails.

Shear nails are inserted through special holes in the sides of the hanger, through the joists at an angle, and the end of the nail lands in the ledger or beam. This locks the hanger, joist, and ledger/beam together, and provides uplift resistance.

Laying Out Joist Hangers

Framing Member

Joists

Joists are the perpendicular framing members that span the deck area where the deck boards are secured. We recommend using joists made of 2x10s for spans less than 14' and 2x12s for spans over 14'.

Most low-maintenance decking, when laid perpendicular to joists, requires that the joists be spaced at 16" on center. When decking is run at a 45 degree angle, joists usually need to be 12" on center.

Spacing deck joists at 12" on center regardless of orientation does help with the flex or bounce of the deck, but this flex can also be mitigated with midspan blocking.

Framing Member

Flush Beam

Decks can be built with the ends of the joists opposite the ledger resting either on top of a drop beam, or secured to the side face of a flush beam.

A flush beam has joist hangers attached to its side, so that the joists butt into the end of the beam, and the top edge of the beam is flush with the top edges of the joists.

Framing Member

Drop Beam

Drop beams support the underside of the joists opposite from the ledger.

Drop beams can also be rotated or moved to a different area beneath the joists, to accommodate for footing locations or deck shapes.

If a deck is being built close to the house but not attached to it, a drop beam may be used to support the side of the deck near the house instead of a ledger. It's installed parallel to the house, and far enough away from it to give its supporting footings some distance from the home's foundation.

Setting Joists

Framing Member

Midspan Blocking

Midspan blocks are short pieces of joist material that are cut and secured between joists. They are installed to stabilize joists and tie them together. This helps spread the deck load between more joists, and makes the deck surface feel more solid.

Framing Member

Post Blocking

Most modern railing systems use posts that have a surface-mount base, meaning that they will mount to the framing beneath the posts. A post base usually measures about 5"x5", and will need a solid blocking area of that size beneath it for the lag screws to screw into.

Because most deck frame members are single or double 2x material, they only make an area 1-1/2" or 3" wide. Adding more layers of framing alongside the existing frame so that the frame is at least 4-1/2" wide beneath the post.

We recommend orienting the blocking the same way the joists are oriented, leaving the full 8-10" of height for the screws to sink into.

Add-On

Joist Tape

Because low-maintenance decking and railing both have such a long lifespan, wood deck framing is usually the part of the deck most susceptible to weathering and rotting. With this in mind, many builders add waterproof joist tape to the top of each joist, which ensures that standing water doesn't rot the top of the joist.

Adding joist tape to all cut faces on stair stringers will keep water from penetrating through the end grain, which is even more susceptible to rot than the top edge of a joist.

Joist tape is usually a black butyl or acrylic tape, and in addition to being waterproof, it makes the joist black on top for a cleaner appearance.

Adding Blocking, Tape, and Bracing

Framing Member

Support Posts

Deck support posts are most often made from wood 6x6s, and are used to support the outer perimeter and sometimes the beams of a deck or landing.

This photo shows posts on the corners of the upper landing, lower landing, and posts on the corner and midway point on the flush beam.

Framing Member

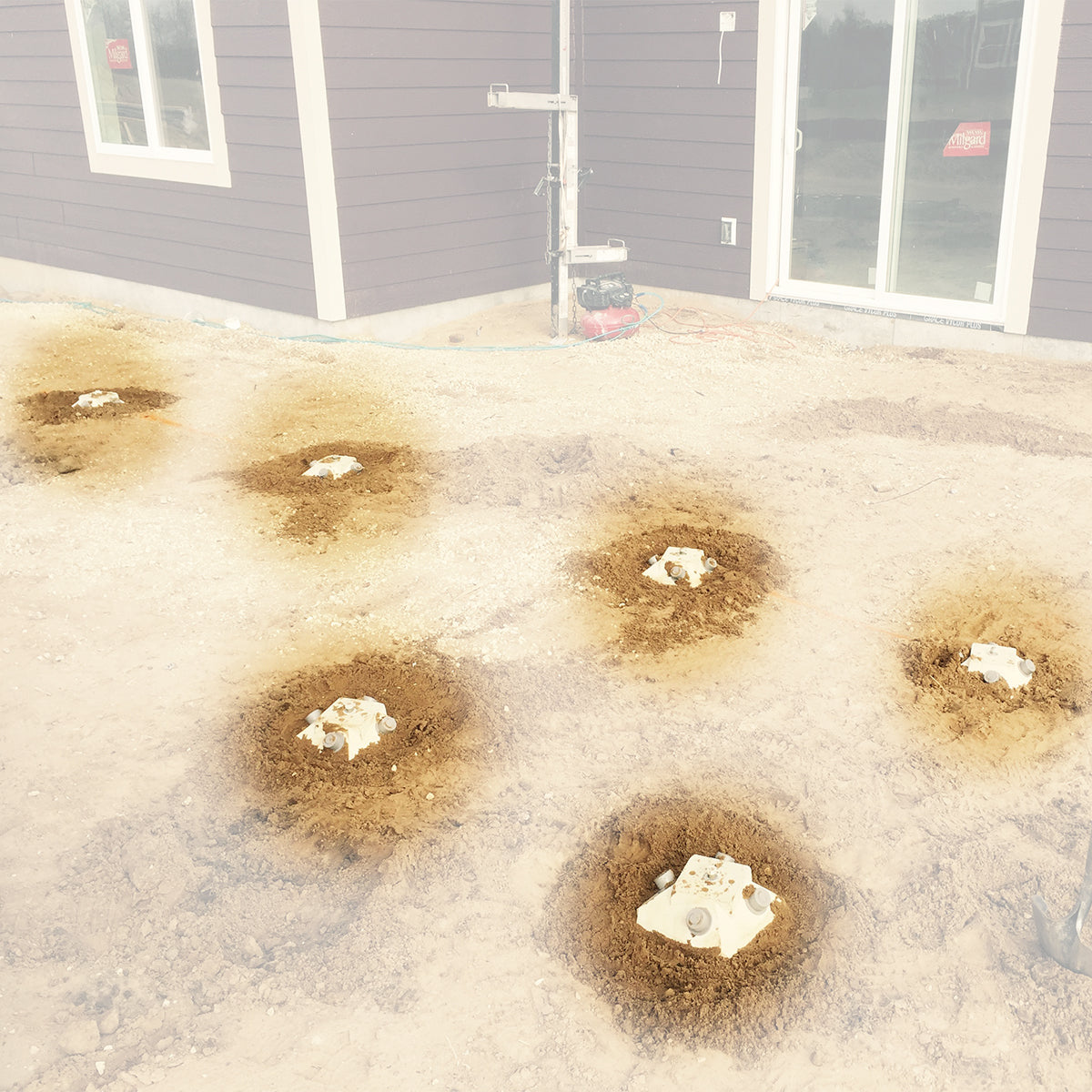

Footings

Every deck support post should rest on some sort of footing, whether that be a Diamond Pier (shown), a helical screw pile, or concrete cylinder.

Footing location is determined by the deck shape, and the frequency or spacing of the footings is determined by the beam spans and therefore the load that the footing would bear.

For example, a 12x12 deck can be supported by a beam with a footing on either end. Those end footings will not need to handle as much weight, and can be the smaller DP-50 Diamond pier footing.

A 16x20 deck, though, is much larger, and there will need to be 3 or 4 footings. If an LVL beam is used, it can span further, so there would only need to be 3 large DP-75 Diamond Pier footings. If a treated beam was used, it wouldn't span as far, and so 4 footings would be needed. Those could be the smaller DP-50 footings, since there are more footings to share the load.

Installing Footings, Posts, and Tension Ties

Stairs

Stair Stringer

A stairway uses 2x12s as a support board that runs beneath the stairway, with trangular shapes cut out of it for treads and risers to be fastened to.

We recommend buying 2x12s and custom cutting each notch out so that it fits your stair length and angle perfectly. This keeps your steps level and consistent. If pre-cut stringers are used, it will almost always result in stair treads that are not level, or steps at the bottom or top that are not the same height as the others.

Stairs

Subtreads

Subtreads give a long, stable surface for the tread to rest on, and helps stabilize the stringers. Some deck boards require a subsurface to be installed. Subtreads also make for a larger surface to secure the treads to, making installation easier.

When using subtreads, a piece of treated 2x material is installed beneath each deck tread, which is most easily made by cutting a 2x10 in half.

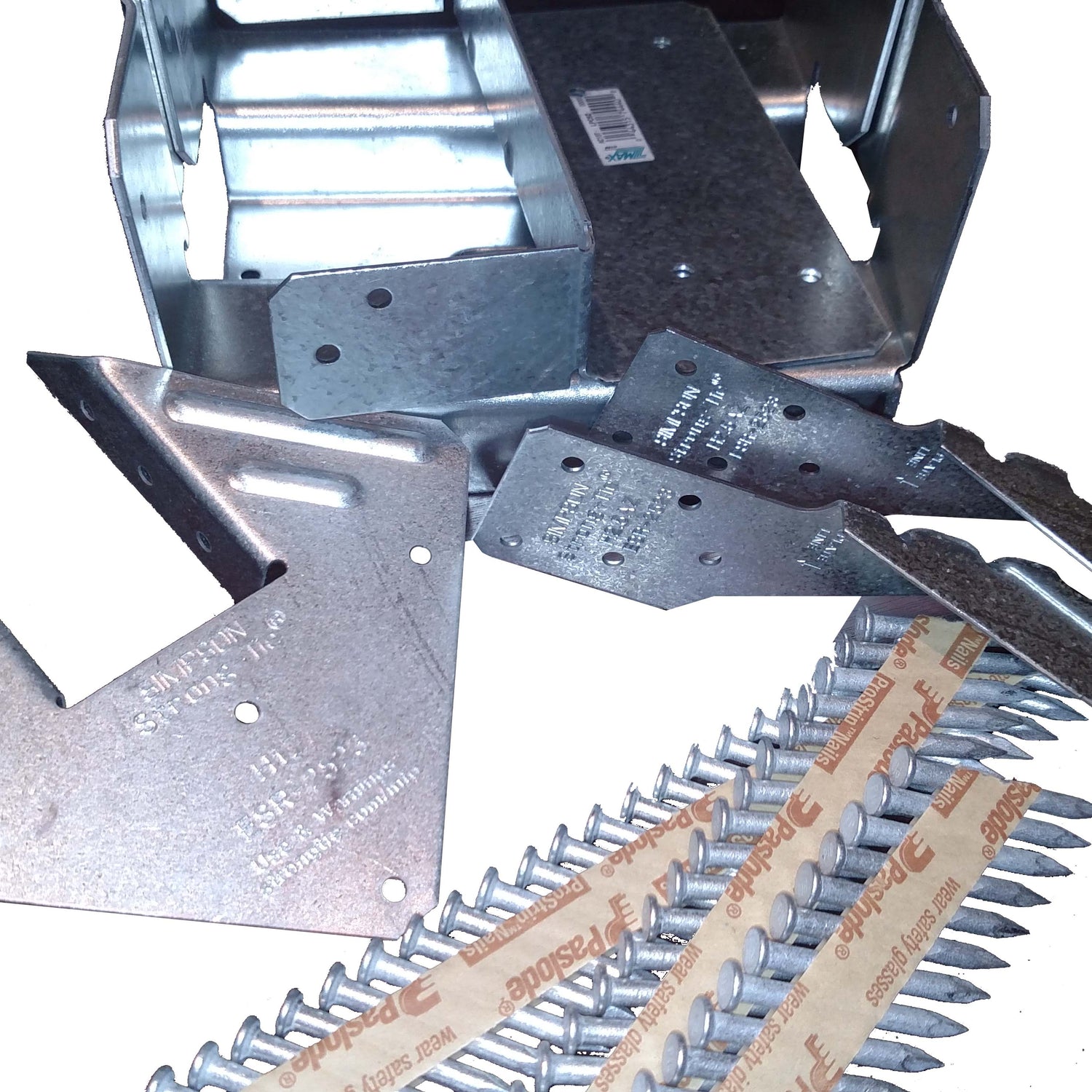

Connectors

Connectors

Many connectors other than joist hangers are used to join lumber together at unconventional or hard-to-fasten joints, for stability and code compliance.

Hurricane ties are used where joists rest on the top of a drop beam.

Post "caps" are used to secure a beam to the post that it is resting on.

Deck tension ties connect the joists to the ledger and house wall, as a backup in case your shear nails in the joist hangers fail.

Stringer straps are used at the awkward connection point between a stringer and the beam at the top of the stair.

Post bases secure a 6x6 or 4x4 post to the top of the footing or Diamond Pier, making sure that it doesn't slide around or lift off of it.