Decking 101

Deck Boards

Deck boards or planks are usually a 1" thick by 6" wide piece of wood or low-maintenance lumber installed horizontally across deck joists to make a walking surface. They can be made of wood, metal, or a combination of plastic, recycled material, and virgin inorganic materials.

Most boards are strong enough to be fastened to joists that are spaced 16 inches apart, as long as they are perpendicular to the joists. If they are angled at 45 degrees, the joists should be spaced 12" on center instead.

Board Composition

Wood-Plastic Composite

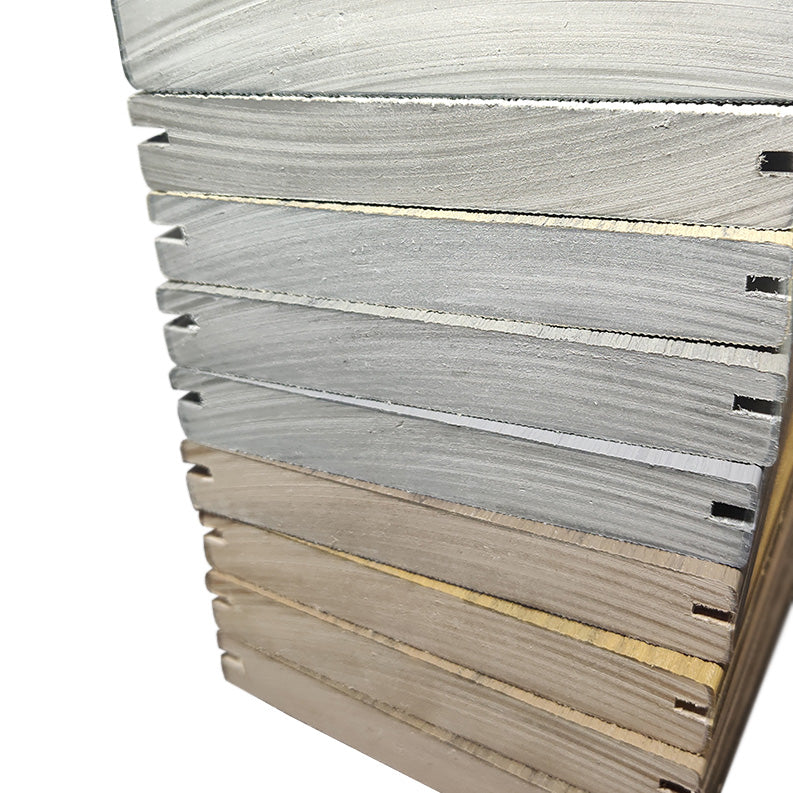

When we hear "composite decking", we often think of any decking that isn't wood or metal. A true wood-plastic composite decking uses wood fibers, virgin or recycled plastic, and resins to create a dense material used as the structural part of a deck board. Neither PVC nor mineral-based decking contains wood, which is why we don't consider it a WPC deck board.

Composite decking was originally designed with the structural material exposed, but because it doesn't weather well, it was quickly revised to have an all-plastic cap that covers the top, sides, and sometimes the underside of the board.

Since wood fibers and recycled material can be acquired at a fairly low cost, WPC decking is generally less expensive than decking made from virgin materials, like PVC.

All of the WPC decking at Pro Deck Supply is capped in some capacity, we do not sell any uncapped composite decking.

Board Composition

PVC

PVC decking refers to decking that is made from polyvinyl chloride, which is an inorganic material that won't rot or absorb water. It is less dense than wood-plastic composite, and can be cut, handled, and fastened more easily.

PVC decking is a cellular composition, which means there are microscopic air bubbles in the board. These air bubbles may expand and contract the board as temperatures change, so if you live somewhere that experiences 90 degree heat in summer and 0-degree temperatures in winter, fastening PVC decking correctly is especially important.

Board Composition

Mineral-Based Composite

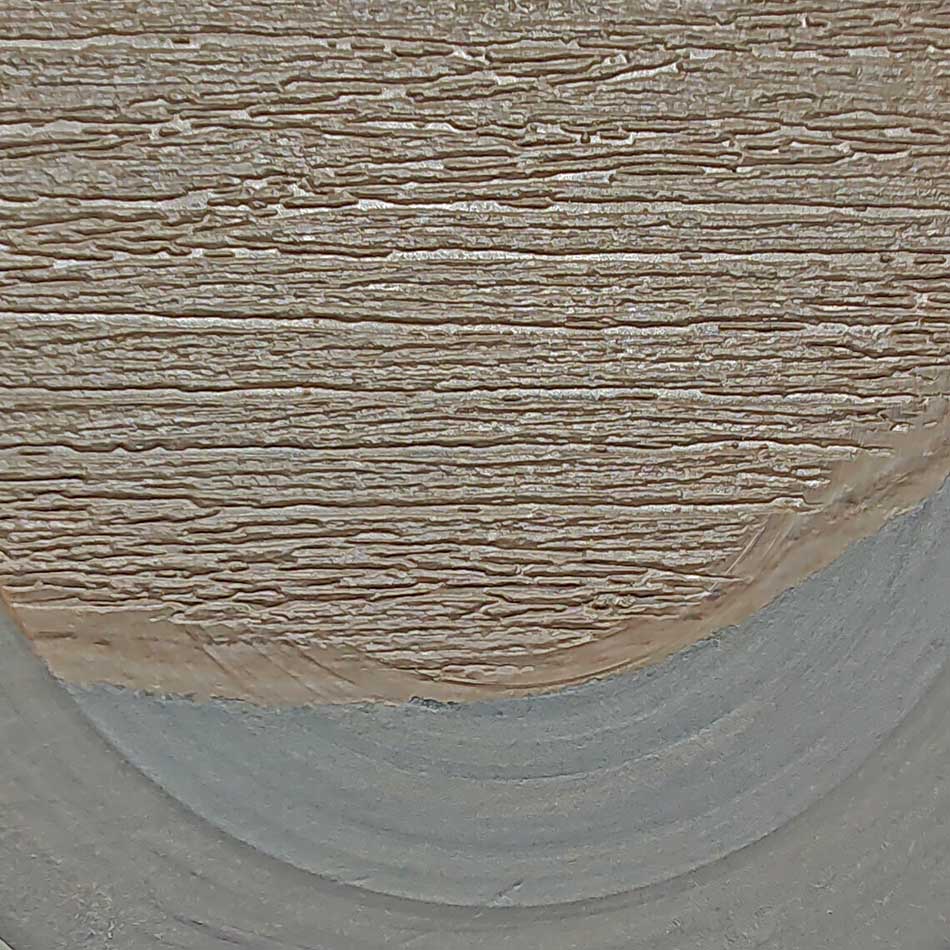

Deckorators has formulated a thermally-stable composition called Surestone for decking and fascia that installs and handles similarly to PVC, but is stronger and more stable.

Surestone is manufactured so that calcium carbonate strands are formed lengthwise in the boards, much like the grain strands in wood boards. These strands are not affected by temperature or humidity, making it a great choice for decking in climates with dramatic temperature swings.

All Surestone boards are capped with a plastic similar to the cover of Titleist golf balls, making it resilient and resistant to scratching. Woodgrain texturing is added for appearance and slip resistance.

Board Composition

Acrylic-Capped Decking

Some decking lines like Trex Signature (WPC) and Zuri (PVC) have a printed woodgrain pattern on their surface, and an acrylic cap is laminated onto the board to protect this layer.

This acrylic layer is textured for slip resistance, and is quite hard, making it more scratch resistance than traditional polyethylene board caps. Sometimes this clear layer causes a greenhouse effect at a microscopic level, which can heat up dark-colored boards to be unbearably hot.

Board Composition

Wood

The lines of wood decking available at Pro Deck Supply are very limited, due to the lower cost and higher durability of composite decking available now.

Wood decking like cedar is still used for its natural beauty, durability in stable climates, and machinability. Wood can also be stained different colors to match the style of your house, but with so many colors of low-maintenance decking available, this feature is almost irrelevant now.

Board Composition

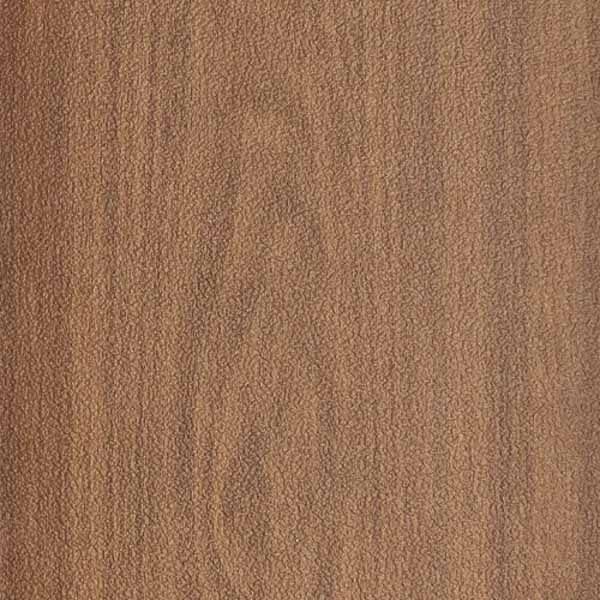

Ipe

Ipe is the more popular wood decking choice at Pro Deck Supply due to its durability and hardness. Though it is more expensive than almost every low-maintenance deck board, it's usually chosen because of its natural beauty, and the fact that it doesn't require much maintenance.

Ipe decking can be left to gray out by leaving it unfinished, or it can be oiled every year or two to help keep its natural warm color.

Board Composition

Uncapped Wood-Plastic Composite

Early versions of composite decking were formulated with recycled paper, sawdust, and recycled material, and may still be found in the history books, but not in any lumberyards. Like many new ideas, early versions of composite didn't have all the kinks worked out. Within only a few seasons, many versions tended to break down, get moldy, have pieces break off, or even turn into dust.

These early versions lacked an weatherproof plastic cap with UV inhibitors, meaning it weathered, grayed out, and would absorb moisture rather easily.

Because the wood filler material was exposed, it would sometimes accept stain or paint, which was seen as an advantage for projects with specific color schemes in mind.