If you're not using an extra-wide engineered beam, chances are that you have multiple layers of framing on your beam.

Why should I bother with nailing or screwing the layers together, especially if it's a drop beam?

The beam members should work together to share the load.

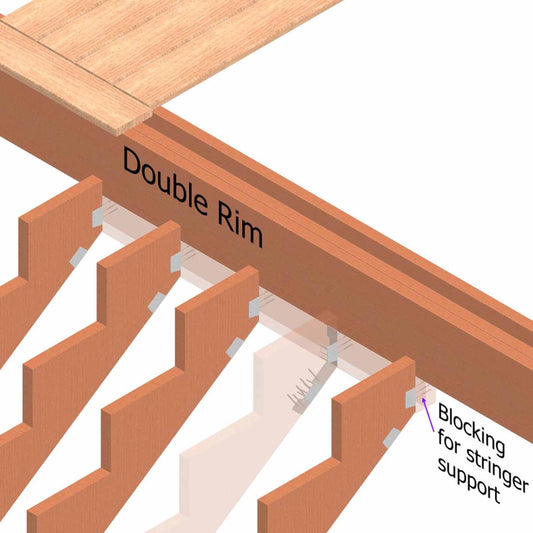

On drop beams, each 2-by-something is likely to be a slightly different size, and they may not be in equal contact with the joists or posts. If your middle layer is 1/4" taller than the others and all the joists are resting on that middle beam, it's going to take the brunt of the load.

On flush beams, all the hangers are secured to the inside beam layer. If your outer layer(s) aren't secured to the ply with the hangers on it, they aren't doing anything other than support your rail. Nailing or screwing the layers together helps the other layers share the load with the joist-hangered ply.

Does it matter what I secure the beam layers with?

Yes, but you have options. First of all, make sure the fasteners are exterior-rated and compatible with treated wood.

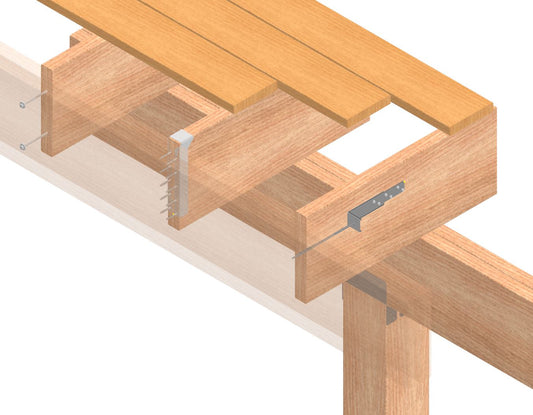

Galvanized 3" nails, especially when used with a nail gun, are the cheapest and fastest option. They won't pull the layers together, but it will help you pass your inspection and help the material load-share.

Exterior-rated screws 1/4"x3" or larger work well to bring the layers together and provide shear strength.

Simpson SWD screws are a unique solution that allows 2+ beam plies to be fastened at once, it brings them together, and leaves only a 1/4" diameter screw head. The small screw head won't get in the way when you're installing your fascia later, unlike a 1/4" lag screw head might.

Check the manufacturer's requirements for the recommended fastening pattern, or ask your building inspector what they'll need to see. It's generally a stacked or W-pattern in a 16" spacing.