With the invention of alternative decking, the possibility of heatforming artificial deck boards integrating curved shapes into decks has become somewhat trendy. It doesn't make design or installation any easier, and may add significant cost if you are hiring a builder, but if you're after a unique deck design, it may be worth it to you.

How does it work?

When heat is applied to plastic or composite boards, they become pliable, and once shaped and held in a mold or template, they will cool and (for the most part) hold their shape.

Forming a board to fit the deck design exactly can be difficult, so curving the board on site is the best way to get a perfect match. The deck is usually framed and partially decked, and the curved section of the decking cut out, so that the board can be placed on the frame adjacent to the curve for the best fit.

What equipment is needed?

Professional deck builders generally use special heating mats or homemade ovens to heat boards to just above 200 degrees Fahrenheit.

The cost of the heating belt kits are in the $4000-6000 range, and may take several weeks since they are made to order. They are generally a long-term investment, and only worth it if you're a contractor looking to do lots of board bending.

Homemade ovens have been made with anything from concrete forming tubes and torpedo heaters to insulated wood frames with multiple hot air inlets. They can be made as one-time-use tools, but it may be worth exploring alternatives before building one yourself.

What framing considerations are needed?

Every deck board needs some sort of framing beneath it, usually 16" on center, so anywhere you have a curved board you should also be installing blocking beneath it. Anywhere you have a curved board, there will be board ends that butt up to the curved board. Every one of those trimmed board ends needs to have blocking within a few inches of the end to be supported properly.

The easiest way to add a curve to the front of the deck is to cantilever the joists over the beam and trim each joist to match the desired curve. As long as you don't cut off the joist where it rests on the dropped beam, it will have adequate support. Keep in mind that most 2x10 treated lumber cannot cantilever over a dropped beam by more than two feet.

What could go wrong?

For the record, be safe. Mixing open flames and wood or plastic can be a fire hazard, and that beautiful curved board can't be installed on a home if it's no longer standing.

If the boards are heated to fast or too hot, the plastic cap can burn or bubble and make it unusable, which means your $40-$200 board will need to be scrapped.

If you're curving to a template separately from the deck, if not done just right, you may need to modify the deck to make the board fit, or scrap the board and try again. Curved boards don't fit into straight ovens very well!

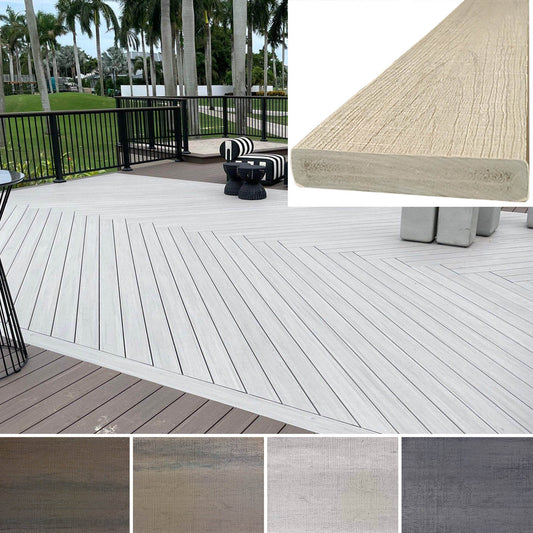

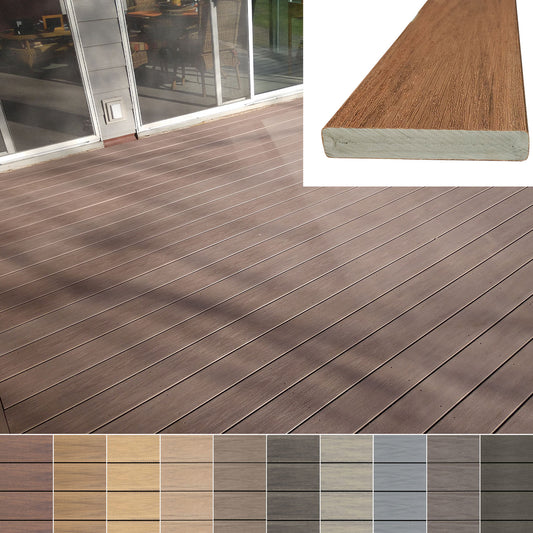

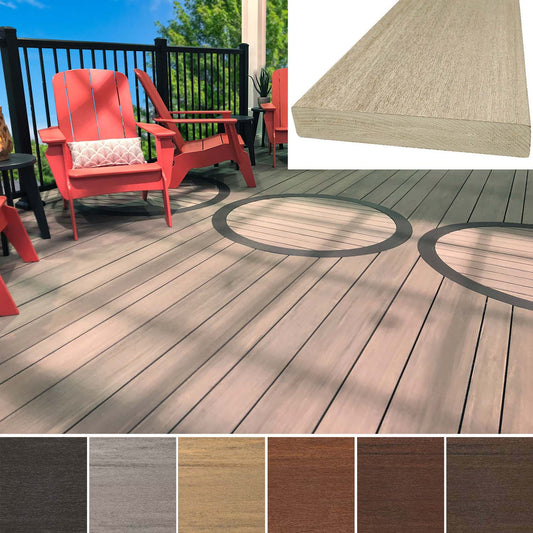

Some decking materials bend more easily than others. PVC decking is the easiest to heat and curve, due to its lower density it heats up more quickly and is more pliable than a wood-plastic composite. WPC decking takes a while to heat up, and more force to bend. Mineral-based composite like Deckorators' Surestone material is quite difficult to bend, we do not recommend it.

What else should I consider?

Building a deck that has a curved front doesn't necessarily mean you need to heatform a board in an oven. You can draw and trim your frame in a hemispherical shape, trim the straight deck boards to match that curve, and install your fascia board around that curve. Typically a deck board is used as a border board to hide the cut edges of the main deck boards, but you can also hide those edges by raising the fascia up an inch or so to cover the edges.

Curved railing panels are possible, but not necessary on curved-front decks. Very few companies can custom-build them, and straight panels can match gentle curves quite well. The time and hassle of getting the curved panels correct may be something best left up to a contractor, due to the precision and ordering details needed.

If you're hoping to add useable space to your deck, designing a deck with curves is rarely going to accomplish this. Unless you have existing landscaping or structures that can be matched better with curves, framing and decking with straight lines will usually be your best option. Even if you have curved landscaping, cutting curved lines out of straight deck boards is a practical way to maximize space without the extra effort of bending the boards.

Can I buy curved boards or rent heatforming mats from Pro Deck Supply?

Unfortunately, we cannot provide board bending services, equipment, or bent boards to either homeowners or contractors. We can certainly work through a design with you that includes curved boards, and supply you with the straight boards, but curving them would be up to you or a contractor with the equipment. We recommend that any board bending is done on the jobsite, since the boards need a precise fit, and the boards may try and go back to their original (straight) shape if not installed immediately.